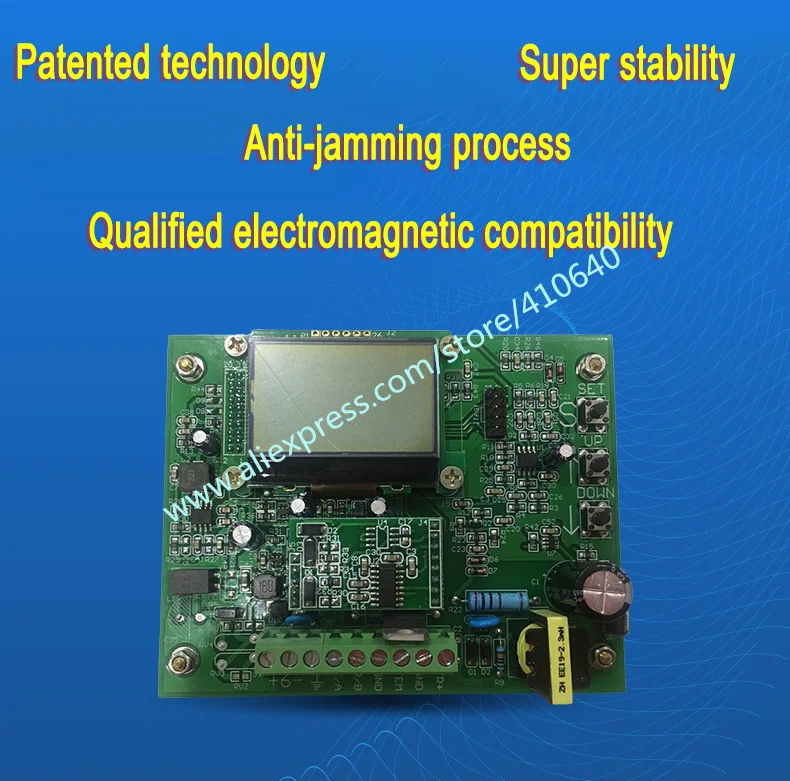

- Model Number: STT-30UWLI24420RS485

- Brand Name: Svit SensoPlan by Trumsense

- Certification: NONE

- Origin: Mainland China

- Display: LCD English Language

- Range: 30 meters

- Power Supply: DC 24V In default

- Outpu: 4 to 20mA and RS485

- Measuring accuracy: 0.5% to 10%

- Resolution: 3mm or 0.1% whichever is better

- Measuring medium: water in default

- Ambient temperature: -20 to 80℃ for probe

- Ambient temperature02: -20 to 60℃ for display instrument

- IP grage 01: IP68 for probe

- IP grage 02: IP65 for display instrument

4-20mA + RS485Output

Ultrasound Water Level Measurement

Ultrasonic Material Position Detecting

Ultrasonic Solid Powder Height Monitoring

Ultrasonic Commercial Concrete Pile Height Measuring

30 Meter Range

24VDC Power Supply

IP68 Ultrasonic Transducer (Probe)

Debugging

Due to the different installation environment of instrument, so before ultrasonic level meter works we must know the basic situation of the required measure, such as measurement range, zero point, full scale and scene working condition.

Technical Parameter:

Important:

1: This link is for power supply is DC 24V, the AC220V or DC 12V is available for extra cost

2: This link is for 4~20mA +RS485 dual outputs, more relay outputs are available with extra cost

3: Explosion proof is available, it need extra cost, contact us for fresh offer.

4: Anti-corrosion probe(ultrasonic transducer) is available, it need extra cost.

5: Second confirm all details with us, before you place order or before our workshop arrange the production or before our warehouse to arrange the shipment for you.

Power Consumption

We are the original factory, if the above parameters can not satisfy your specific needs, contact at any time, our technician team will offer you the proposal within 24 hours.

Ordering Guide

1. Measuring media?

2. Media’s temperature and pressure?

3. Is your measuring media corrosive?

4. Need ex-proof , anti-corrosive?

5. Measurement range?

6. Working environment/condition?

7. Working voltage: 24VDC is standard ; 220VAC is optional ;12VDC/9VDC can be customized

8.Signal output: 4~20mA or RS485 or RS232?

9: Connection method?

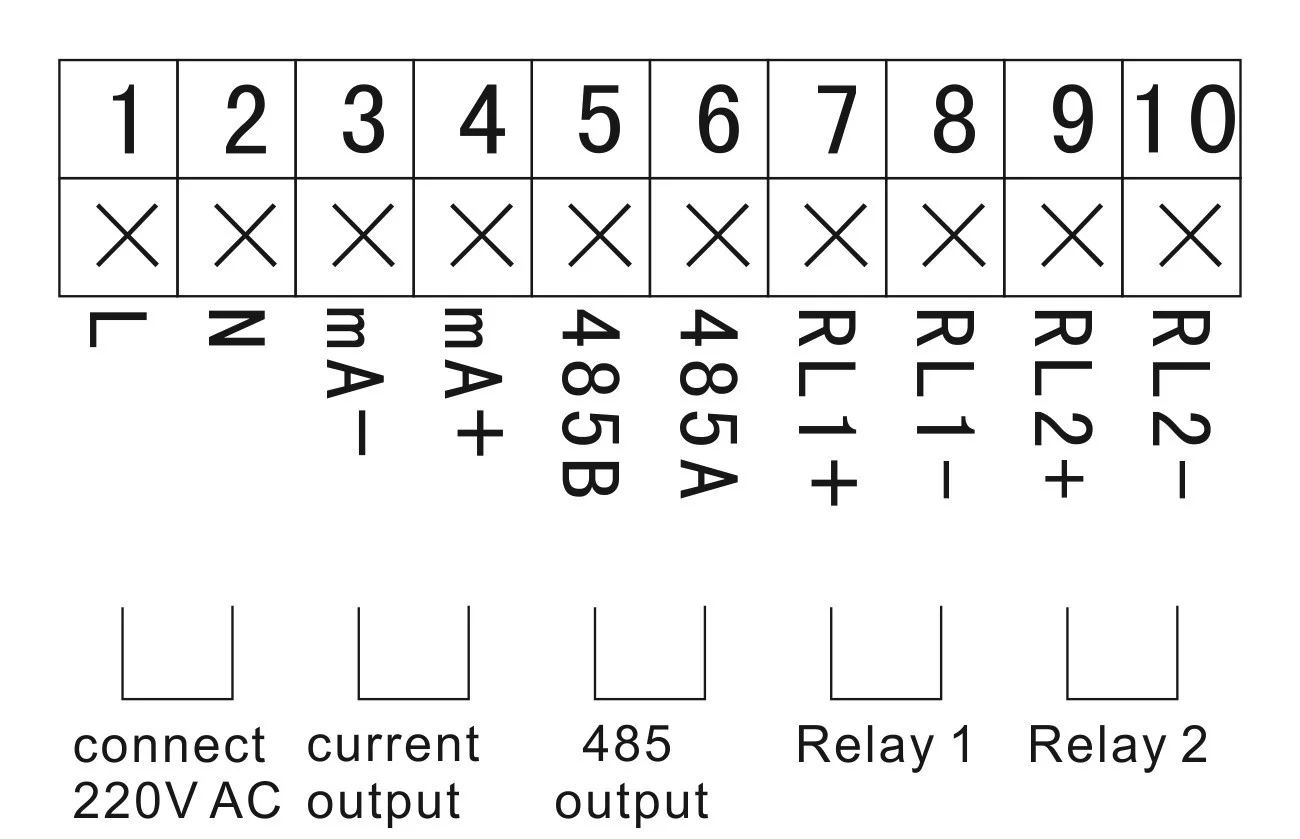

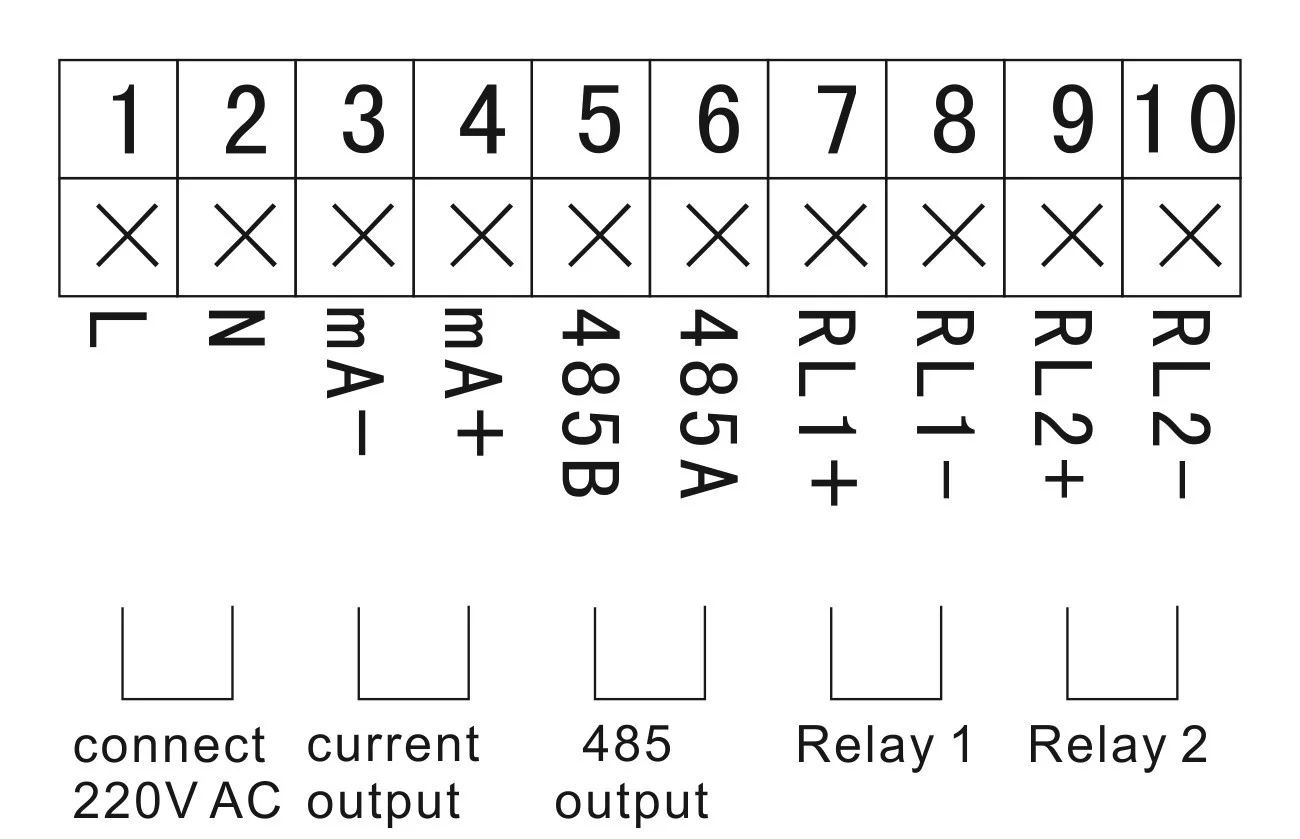

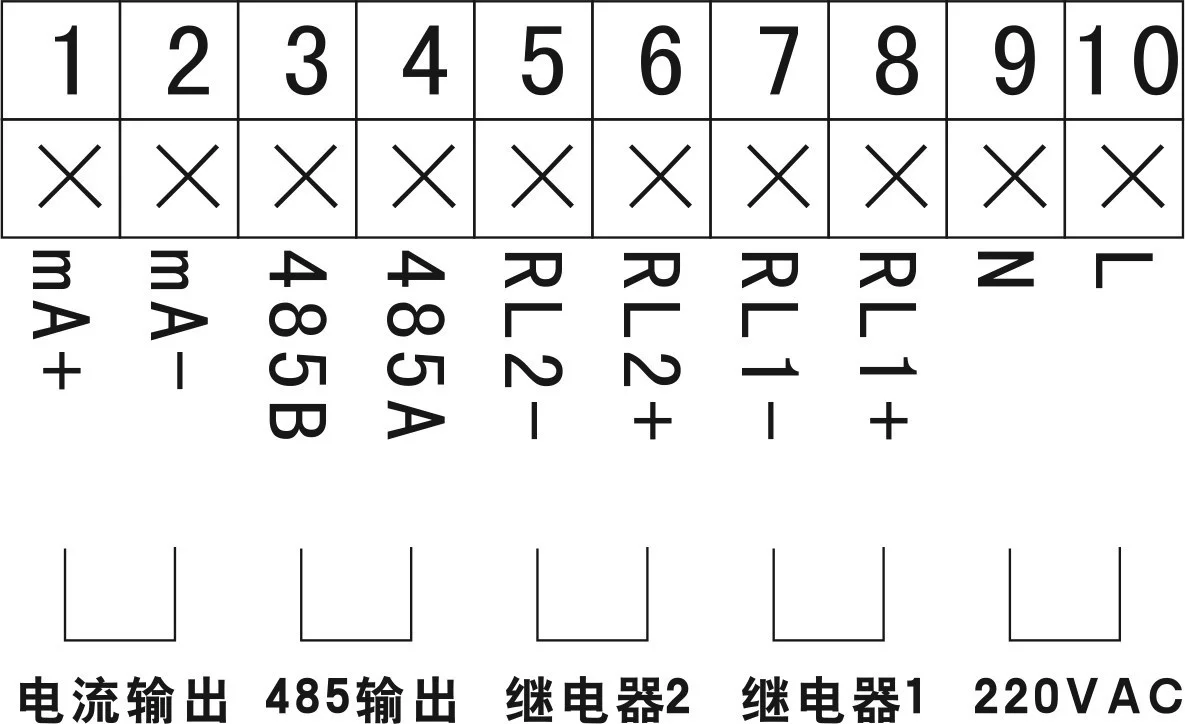

Wiring Diagram:

● Prompt: make sure the connecting cable between the probe and meter body of separate-type ultrasonic level meter is long enough in advance. Connection with other cable for extension on site is not allowed as it will affect the signal transmission quality and strength.

● During power line connection, AC power line shall not be connected to any other terminals except AC terminals. Otherwise, the meter circuit or components and parts will be burnt.

● 485, 232 and 4-20ma output terminals shall not be short-circuited as short circuit will lead to burning of internal circuits.

● The cables connecting the sensor and main equipment shall not be put in a trunking with any alternating current. If it can not be prevented, the cables of sensor shall be protected by a cable conduit to completely shield the electromagnetic interference caused by alternating current.

Wiring method:

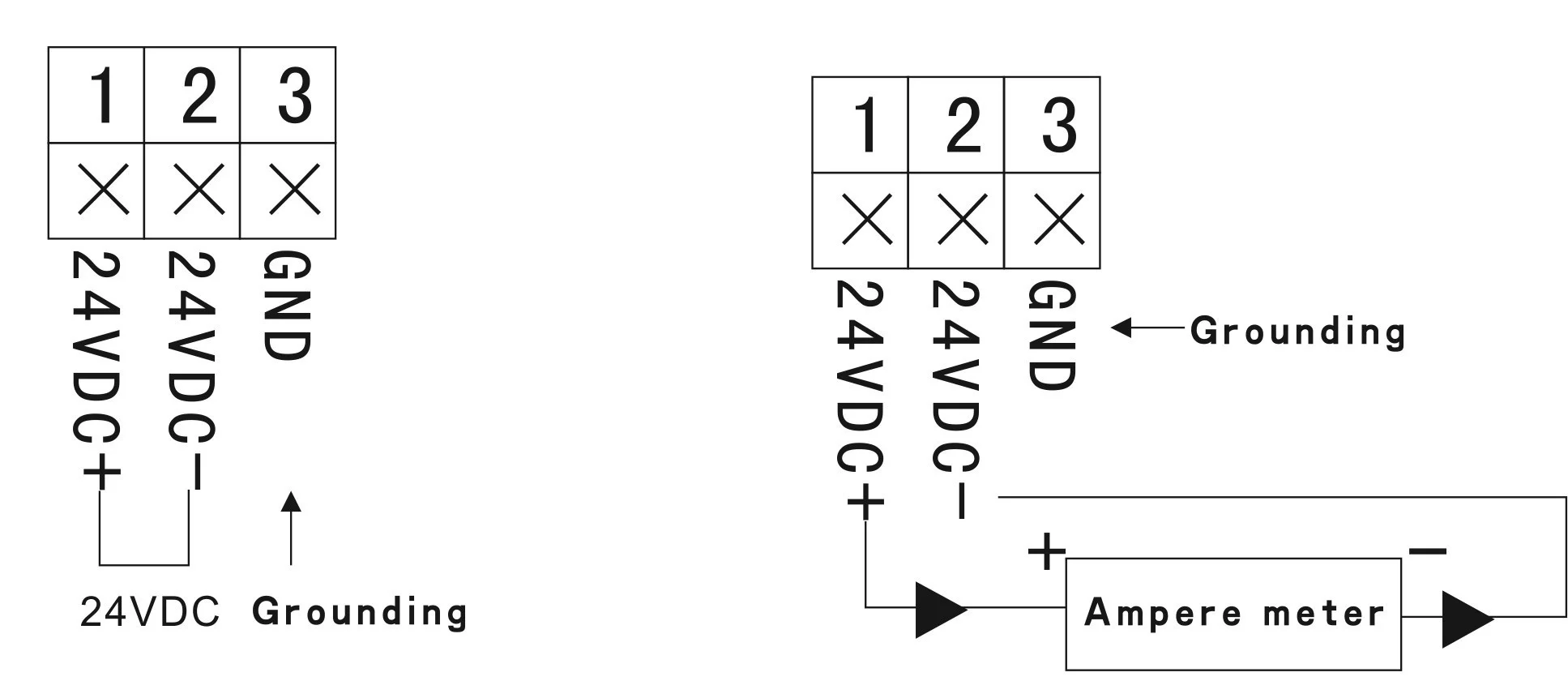

Grounding: first make sure the grounding terminal of the meter is actually grounded and the meter does not share ground terminal with other equipment and then connect terminal 4.

Transducer: red wire: connected to Trans1 (transducer);

blue wire: Temp 1 + temperature sensor +

Black wire: GND (ground wire)

Current output: “current +” connected to mA1 +;

“current -” connected to mA- /GND

Relay: RLlnA and RLnB are normally open;

To ensure the default state of relay is “normally open”, RLlnA and RLnB shall be connected.

RlnA and RLnC are normal closed.

To ensure the default state of relay is “normally closed”, RLlnA and RLnC shall be connected.

Power line: AC: connected to L and N

DC: 24V+ connected to 24VDC+ and 24V- connected to 24V DC-.

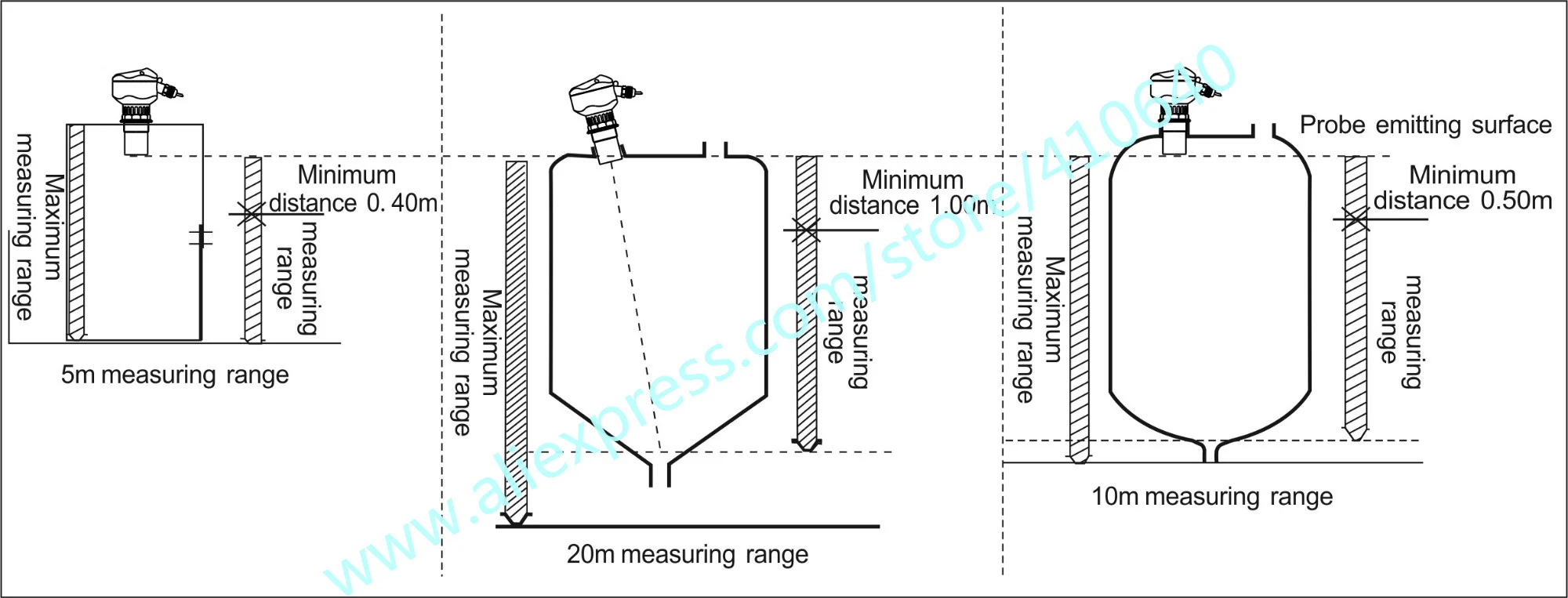

◆ Enhanced integrated type with four-wire system

Electric Wiring Diagram of Enhanced Integrated Type with Four-wire System:

24VDC Power Supply Wiring Diagram of Four-wire System:

220VAC Power Supply Wiring Diagram of Four-wire System

Electric Wiring Diagram of Two-wire System

Wiring Diagram of Two-wire System + Ampere Meter Diagram of Two-wire System:

◆ Explosion-proof integrated type with four-wire system

Electric Wiring Diagram of Explosion-proof Integrated Type with Four-wire System

24VDC Power Supply Wiring Diagram of Four-wire System:

220VAC Power Supply Wiring Diagram of Four-Wire System:

◆ Explosion-proof integrated type with two-wire system

24VDC Electric Wiring Diagram of Explosion-proof Integrated Type with Two-wire System

Wiring Diagram of Explosion-proof Integrated Type with Two-wire System +

Connection of Explosion-proof Integrated Type with Two-wire System and Ampere Meter:

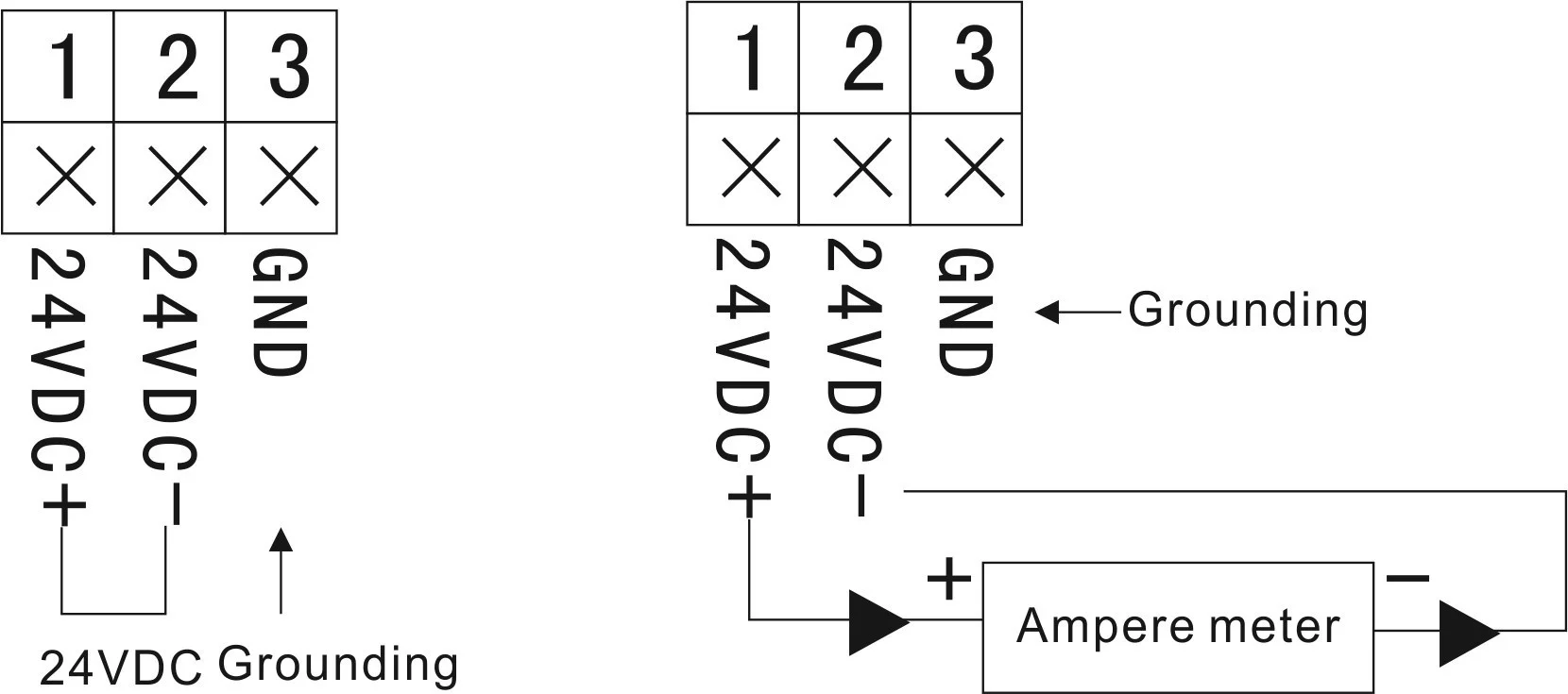

Installation Guide

It is important for the users to understand the below terminologys before the installation operation:

1: Measuring range: the meaning of measuring range is very important for meter type selection. Please refer to the diagrams below:

2: Emitting angle and false echo:

Ultrasonic wave beam is gathered by the probe. The emitting of impulse wave beam is like the light beam of flashlight. The further it is from the probe, the greater the diffusion area is.

Any objects within the range of emitting angle, such as pipe, support, weld joint, reinforcing rib, mixing propeller and hanging object, will lead to strong false echo, specially the objects within the range of emitting angle which are near the probe.

For example, the false echo caused by the pipe at 6m from the probe is 9 times stronger than that caused by the same pipe at 18m from the probe.

★Try every effort to make the sensor axis perpendicular to the medium surface and avoid any other object within the range of emitting angle, such as pipe and support.

Typical Wrong Installation (only examples):

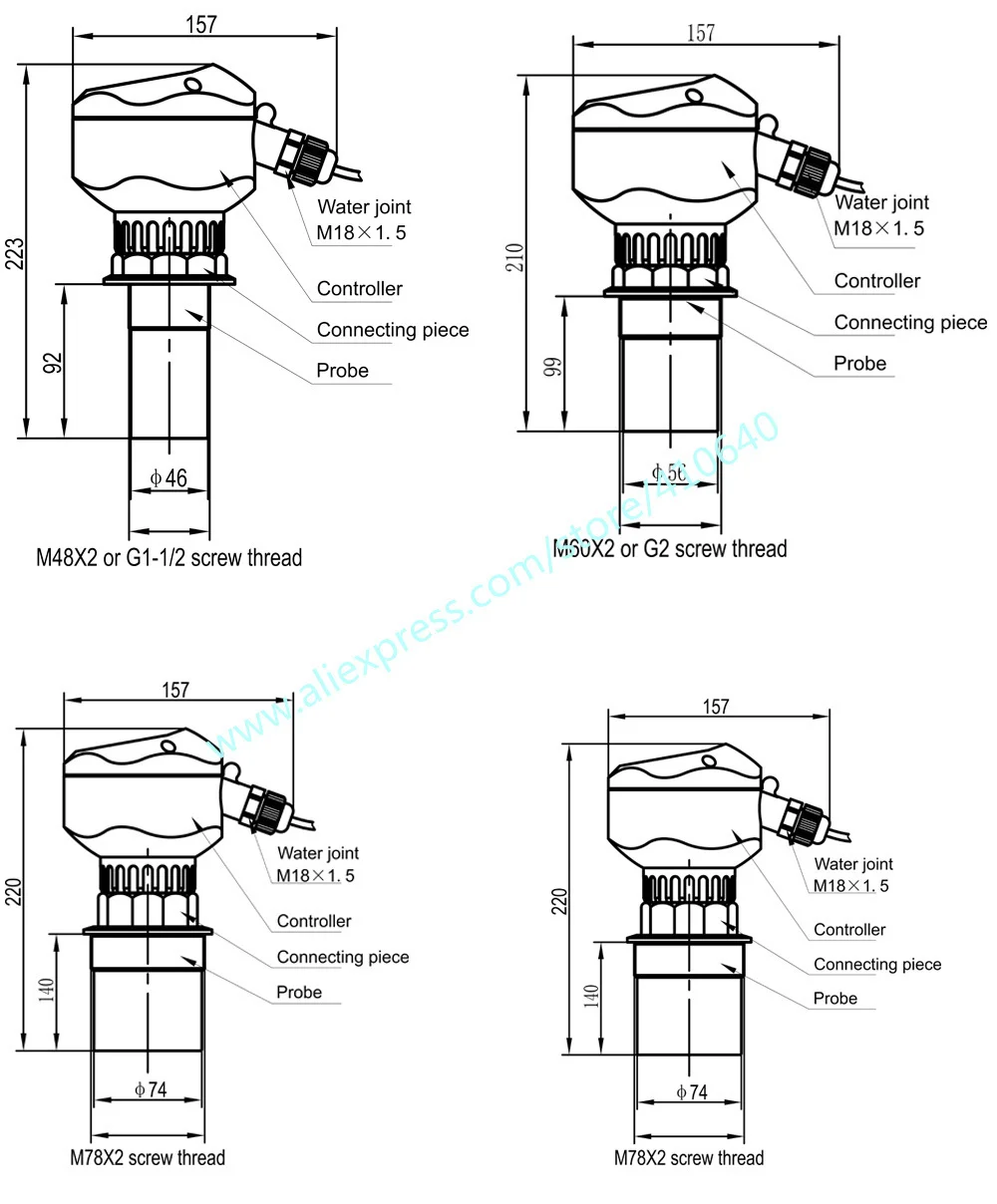

Sizes of Integrated Ultrasonic Water/Material Level Meter

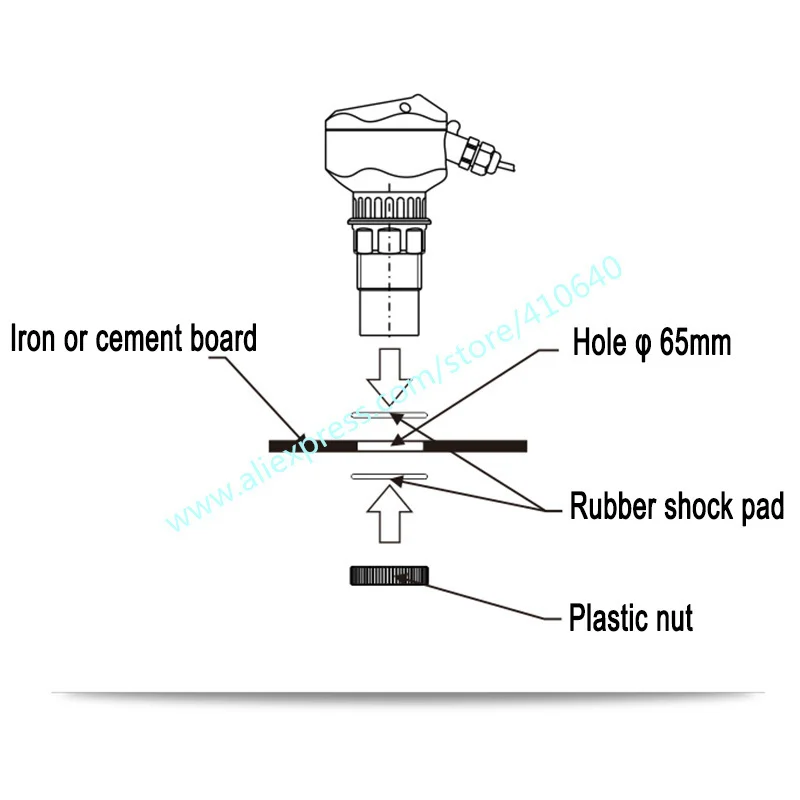

Installation of thread at the bottom:

★After probe installation, the probe emission surface must be exposed from the cover plate or waveguide and it shall not be in the cover plate or waveguide.

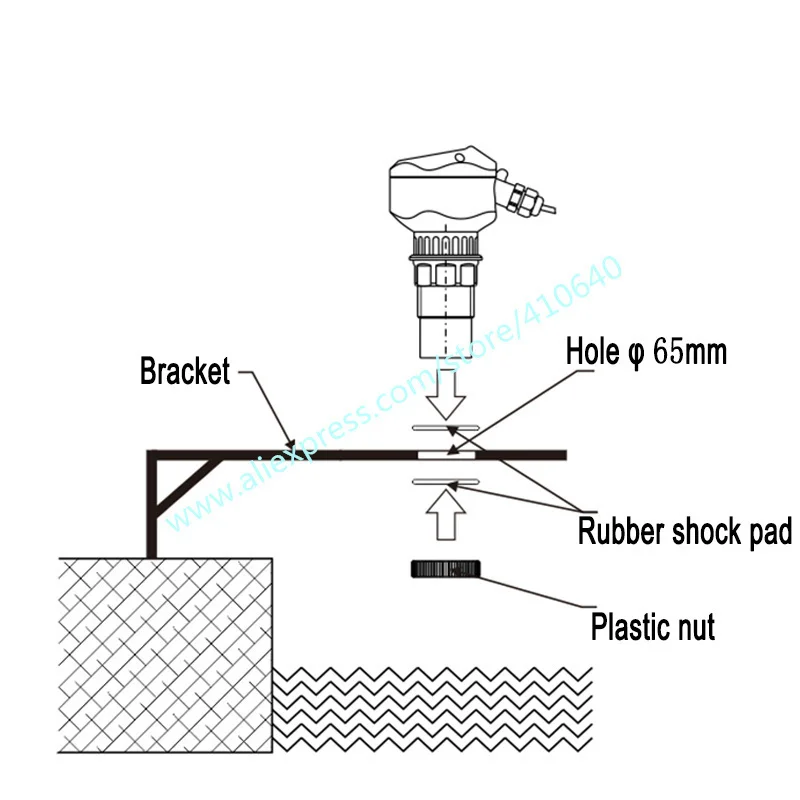

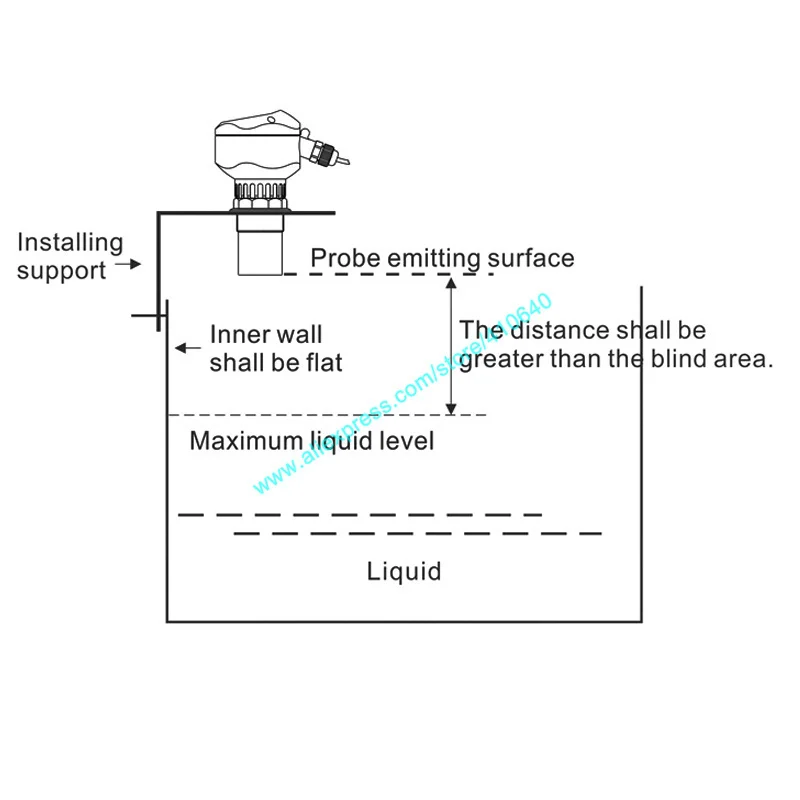

Open container Installation:

For open container, the support shall be used for installation. The bearing capacity of support shall be noted and certain distance shall be kept between the sensor and container wall. If the upper part and lower part of the open container or stock bin inner wall are flat and free of hanging objects and any other objects, the distance between the sensor and container wall is detailed as follows:

Installation on open container – with top against the support at one side:

As the open container has no focusing effect, the sensor can be installed in the middle of the container.

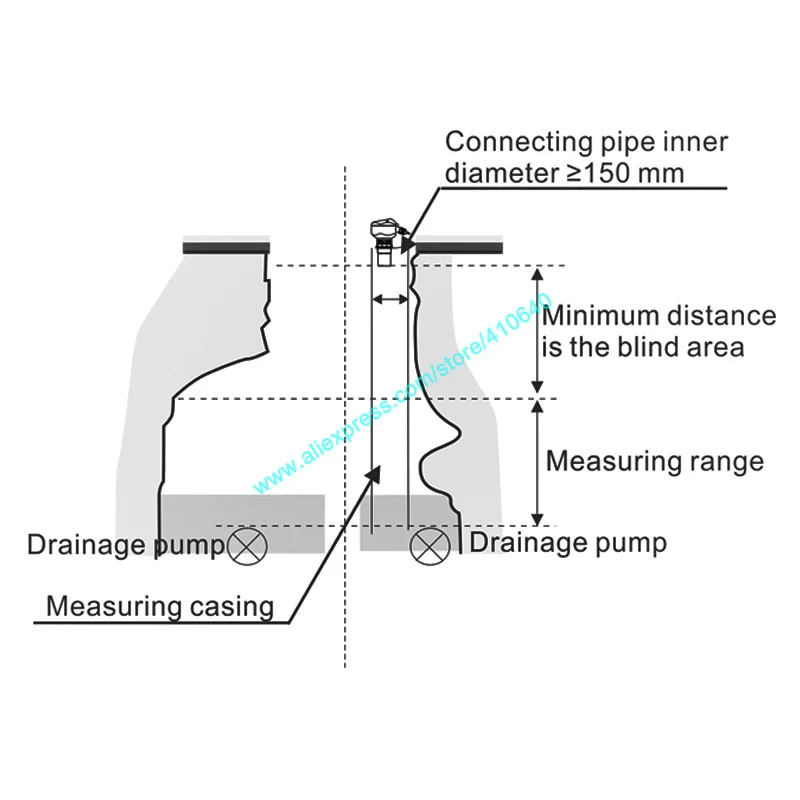

Draining well and common well Installation:

Normally, the wellhole and wellhead of drainage well are narrow and the well wall is uneven, which makes it difficult to conduct ultrasonic measurement. This can be solved by installing a section of connecting pipe or a whole measuring casing. Attention shall be paid to the fact that the blind area will be enlarged for about 50~100% after the sensor is put into the connecting pipe. So the factors for blind area expansion shall be considered.

Thus, when the connecting pipe is used, if the original probe blind area is 0.50m, it will be enlarged to 1.00m after the probe is put into the connecting pipe.

● For common well (including water source well and deep well), normally the diameter is small and the best measuring effect can be reached by installing measuring casing. The inner wall of measuring casing must be smooth (PVC and PE pipe can be used) and the inside diameter shall be ≥150mm (measuring range within 4m). The manufacturer shall be contacted for connecting pipe longer than 4m. The measurement can be carried out as long as the measuring casing is clean and free of attached medium and internal joint.

The measuring casing shall be soaked in the medium all the time, which can ensure the accurate measurement within the measuring casing.

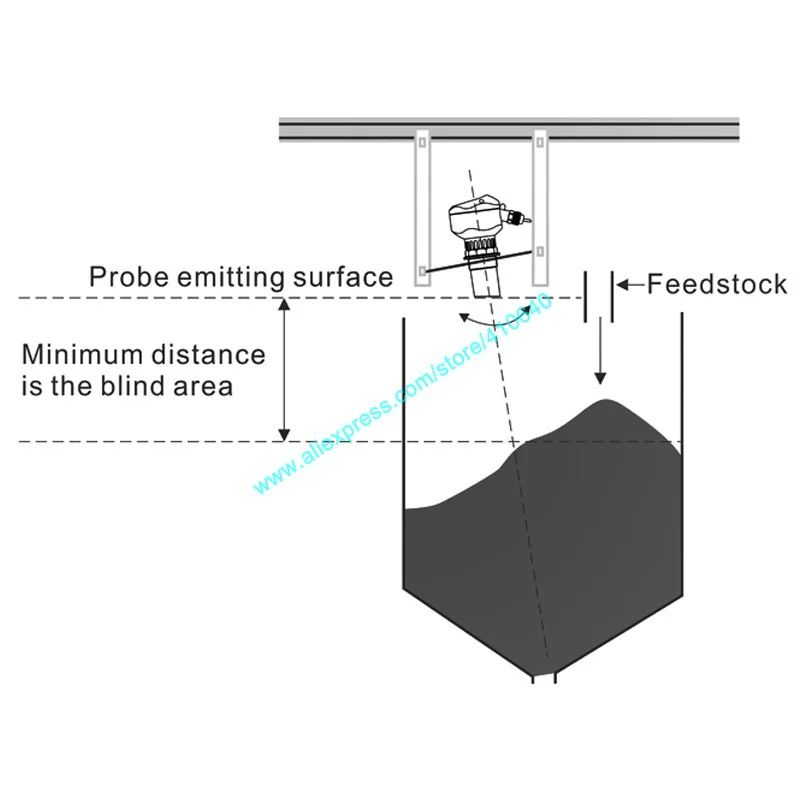

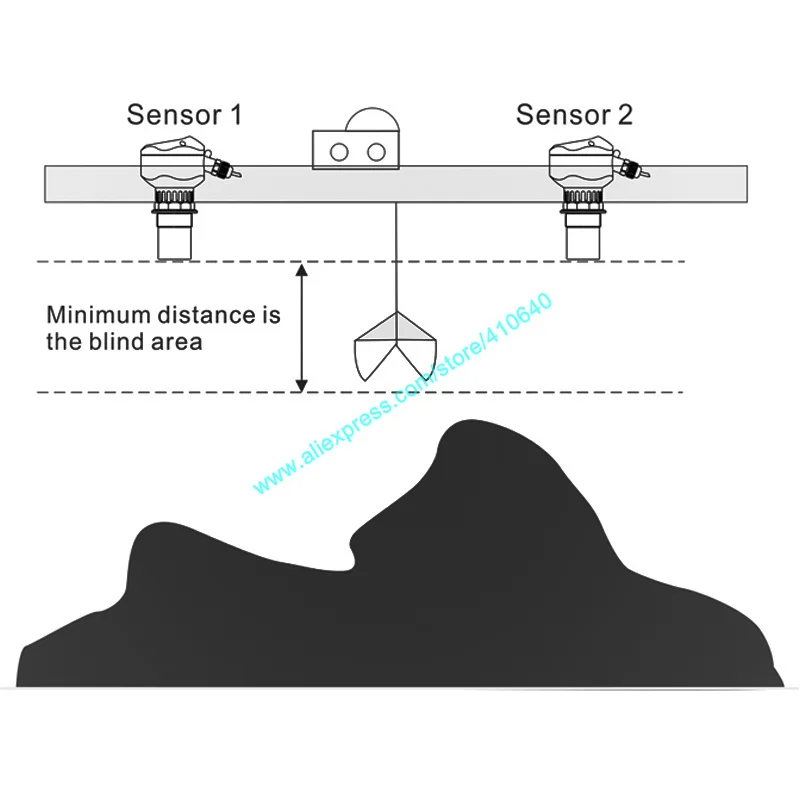

Doorframe installation for solid measurement:

Doorframe installation can be applied for the open container and the axis of connecting pipe must be aligned to the container opening or perpendicular to the medium surface.

During installation for material piles in the open air, several meters are required for the measurement of large material pile in the open air. The meters can be fixed on the hoist frame and sensor probe shall be aligned to the medium surface.

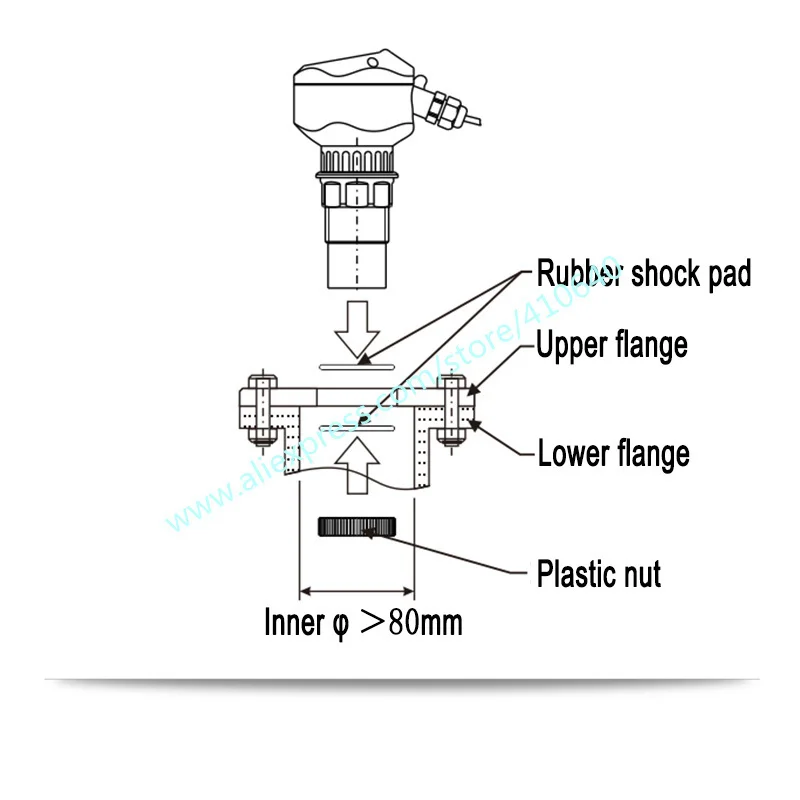

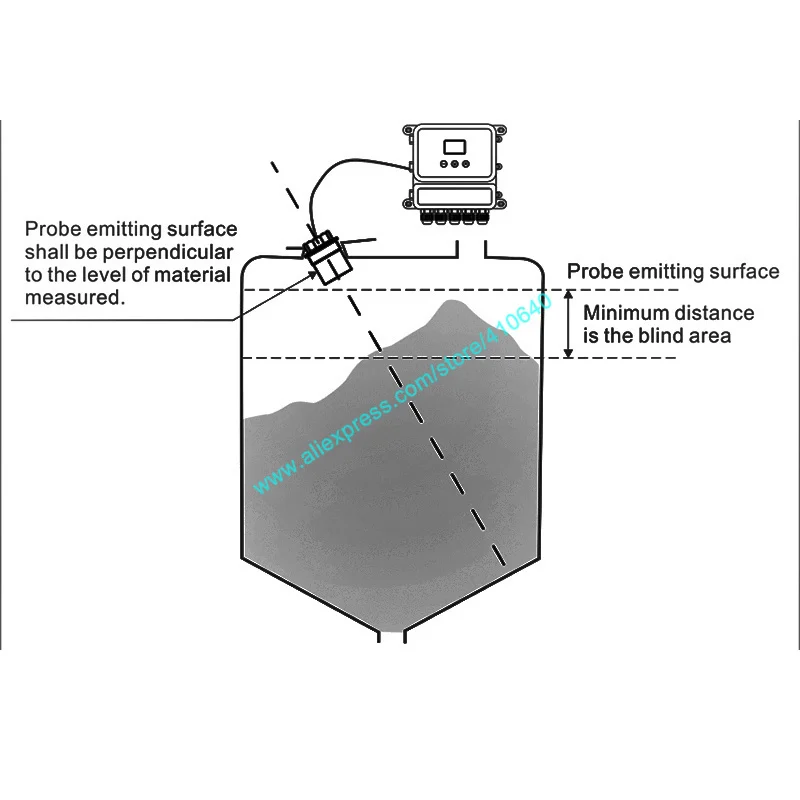

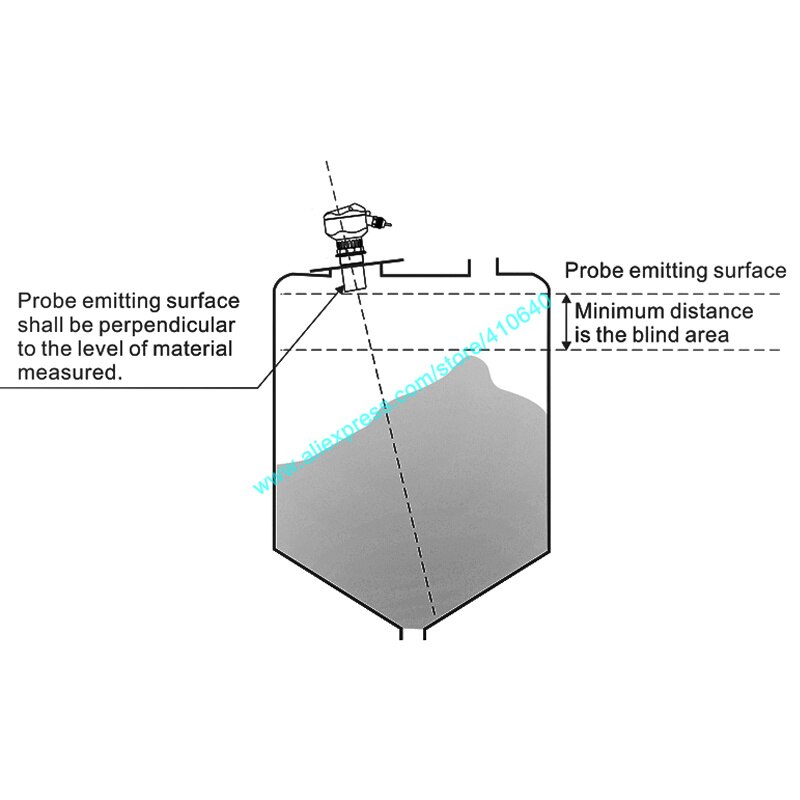

Flange installation of Solid Measurement:

Similar to liquid medium measurement, the meter can be installed on the counter flange of container connecting pipe. The solid reflecting surface is different from that of the liquid and it is not a plane, which shall be considered during installation. The probe emitting surface shall be perpendicular to the surface of solid to be measured and the probe shall be exposed from the connecting pipe.

At the solid measurement site, in most cases, probe inside the connecting pipe will lead to pulsating of measured data or “wave loss”.

To solve the problem, the universal flange can be used. In this case, the probe emitting surface can easily be aligned to the reflecting surface of the solid to be measured merely by rotating the flange.

Take Separate-type sensor installed on container flange as example:

Faults and Handling

If all wirings are normal through inspection in case of a fault, after ultrasonic level meter is grounded, you can keep pressing "▲", then press "SET" to show echo menu, take a photo of the echo menu and send it to us via MMS or picture. By this way, we can determine the possible electromagnetic interference, false echo, situation of entering a blind area, no echo signal received and other faults.

|

Faults |

Causes |

Handling |

|

Level meter does not work. |

Power supply is not well connected. |

Inspect power line. |

|

Level meter does not display data. |

1.Power supply is not well connected. 2.Wiring between LCD and mainboard falls off or comes loose. 3.The LCD is damaged. |

1.Inspect power line. 2.Inspect the wiring and connect it again. 3.Maintain it in the factory. |

|

Level meter works but there is no change of trumpet icon (▲) on the LCD, which means that the system is in wave loss state. |

1.The measured area is beyond the measuring range of level meter. 2.The measured medium has strong disturbance, vibration or heavy dust. 3.There are strong interference sources around such as frequency converter and motor. 4.The probe is not aligned to the measured surface. 5.There are redundant objects in the measured space, such as support rod and feed opening. 6.The liquid level is in a blind area. 7.The measured medium is soft powder or there is foam on liquid surface. |

1.Replace the level meter with a level meter with greater measuring range. 2.The meter will restore the normal measurement automatically after the measured medium gets back to calm. 3.Check surrounding environment and realize good electromagnetic shielding. Do not share one power supply with frequency converter and motor, and make it grounded reliably. 4.Reinstall probe and make it perpendicular to liquid surface. 5.Select an appropriate position for installation and prevent an interfering object. 6.Raise the installation position of probe. 7.Check whether the medium is powder. If so, consult the manufacturer. |

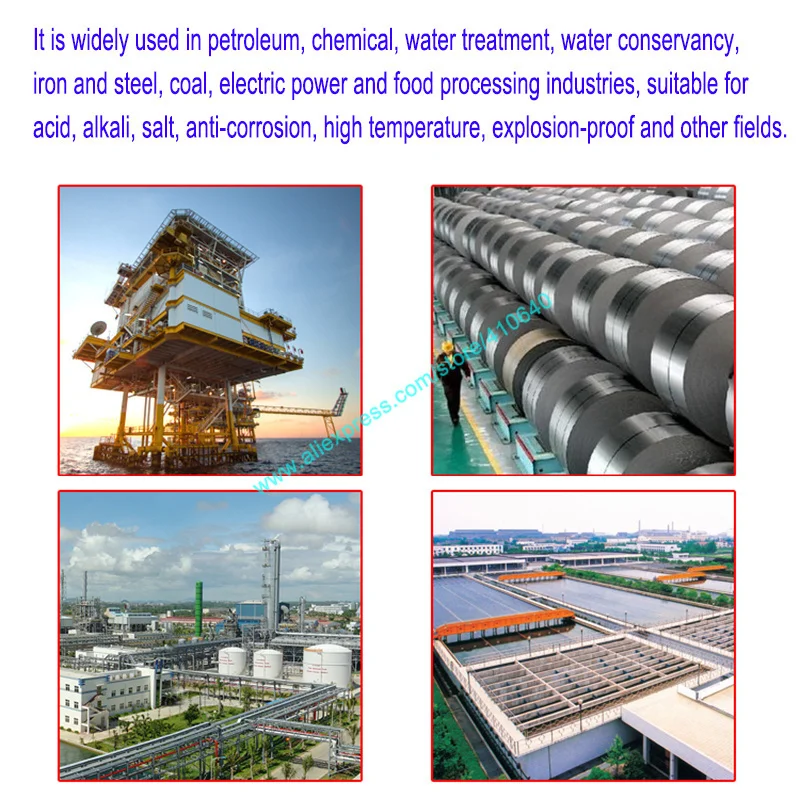

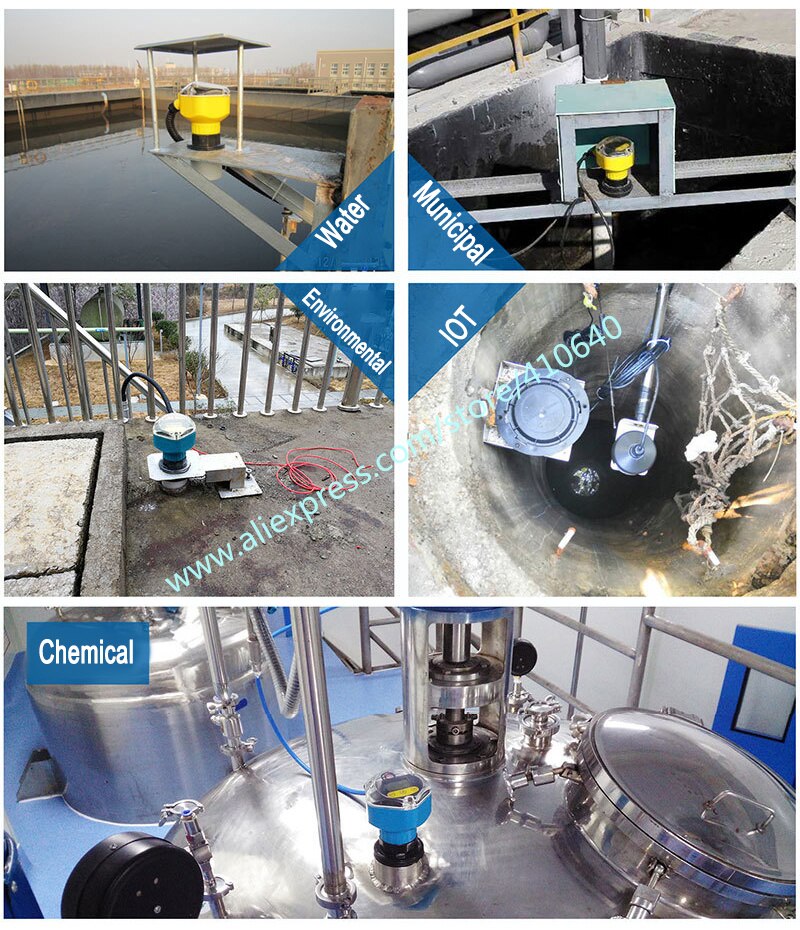

Application Examples

Liquid level and material level measurement is a common problem in industry. Ultrasonic position measurement technology has many advantages. It can not only measure position at fixed point and continuously, but also provide signals needed for telemetry or remote control. Compared with radioactive positioning technology, ultrasonic technology does not need protection. Compared with laser ranging technology, it has the advantages of simple and economic. At the same time, ultrasonic technology generally does not require moving parts, so it is relatively convenient in installation and maintenance. Ultrasonic level meter can be widely used in petroleum, mining, power plant, chemical plant, water treatment plant, sewage treatment station, agricultural water, environmental protection monitoring, food ( brewing industry, beverage industry, additives, edible oil, dairy products ), flood control, hydrological monitoring, open channel, spatial positioning and many other industries.

Important:

1: Standard power supply is DC 24V, the AC220V or DC 12V is available for extra cost

2: Standard output is 4~20mA, if you are in need of RS485 or more relay, contact us for best price.

3: Explosion proof is available, it need extra cost, contact us for fresh offer.

4: Anti-corrosion probe(ultrasonic transducer) is available, it need extra cost.

5: Second confirm all details with us, before you place order or before our workshop arrange the production or before our warehouse to arrange the shipment for you.

We are the original factory, if the above parameters can not satisfy your specific needs, contact at any time, our technician team will offer you the proposal within 24 hours.

Ordering Guide

1. Measuring media?

2. Media’s temperature and pressure?

3. Is your measuring media corrosive?

4. Need ex-proof , anti-corrosive?

5. Measurement range?

6. Working environment/condition?

7. Working voltage: 24VDC is standard ; 220VAC is optional ;12VDC/9VDC can be customized

8.Signal output: 4~20mA or RS485 or with GPRS ?

9: Connection method?

Why you should purchase from us?:

Reviews

There are no reviews yet.